Modifying the i1i0 table

for the i1pro2

The X-Rite i1pro 2 is

backwards compatible in most ways with the original i1pro

spectrometer,

with the basic dimensions, aperture hardware, and driver being very

compatible. One area where

it is subtly different is in working with existing i1i0 tables. The

body of the i1pro2 is a little

lower, the foot is continuous rather than having a gap, the sides

are straighter, and the head a little

larger in diameter. Given the form fitting cradle in the i1i0, the

end result is that the i1pro2 won't

fit into an existing i1i0.

X-Rite has a scheme to allow existing i1i0's to be upgraded:

<http://www.xrite.com/product_overview.aspx?ID=1959>,

but for some of us not in North America, or who have not paid the

local distributor an outrageous price margin

for the privilege of buying it via them, this is not such an

attractive proposition.

Since It seems to be a simple mechanical issue, I thought I'd see

about modifying an existing i1i0 to solve this problem.

What follows is the result.

WARNING: This is not for the

feint of heart. If you are not the sort of person who has the

experience

and confidence in your ability to carry out changes that involve

carving away parts of an expensive piece

of kit and returning it to working order, don't attempt to emulate

what follows. Read it for entertainment

value only. It will void you warranty. You have been warned!

Removal

The first step is to remove the transparent foot. First detach the

arm from the main plate in the usual way,

and turn it over. Next remove the grey half-circle cover plate -

there is a small opening at the peak of the

circle to release the clip, or you could gently lever it from from

the ends. Next step is release the foot from its main

pivots, being careful not to tug it too far, since there is a cable

attached, and watch out for the counter-weight

rod and spring. The last step is to release the plug and cable, but

this needs to be done carefully so as not

to put too much tension on the spring, or you will break it's anchor

point (I found this out the hard way).

With the tension released, the spring can be detached from the foot.

The foot is in two pieces, an upper and lower, and is joined in

three places, two hooks at the rear,

and an internal molded clip at the front. You probably want to

remove the glide and its metal retaining clip, the clip

needing the small spring unwound in order to release it. The

internal molded clip is very hard to release, even though

you can get to it from the inside. It needs to be pushed outwards,

but since it is going to be discarded anyway,

the best approach is probably to work it until it snaps off

internally. This is because the two pieces are

going to have to be fitted together many times, and the clip will no

longer be a practical fastener.

Destruction

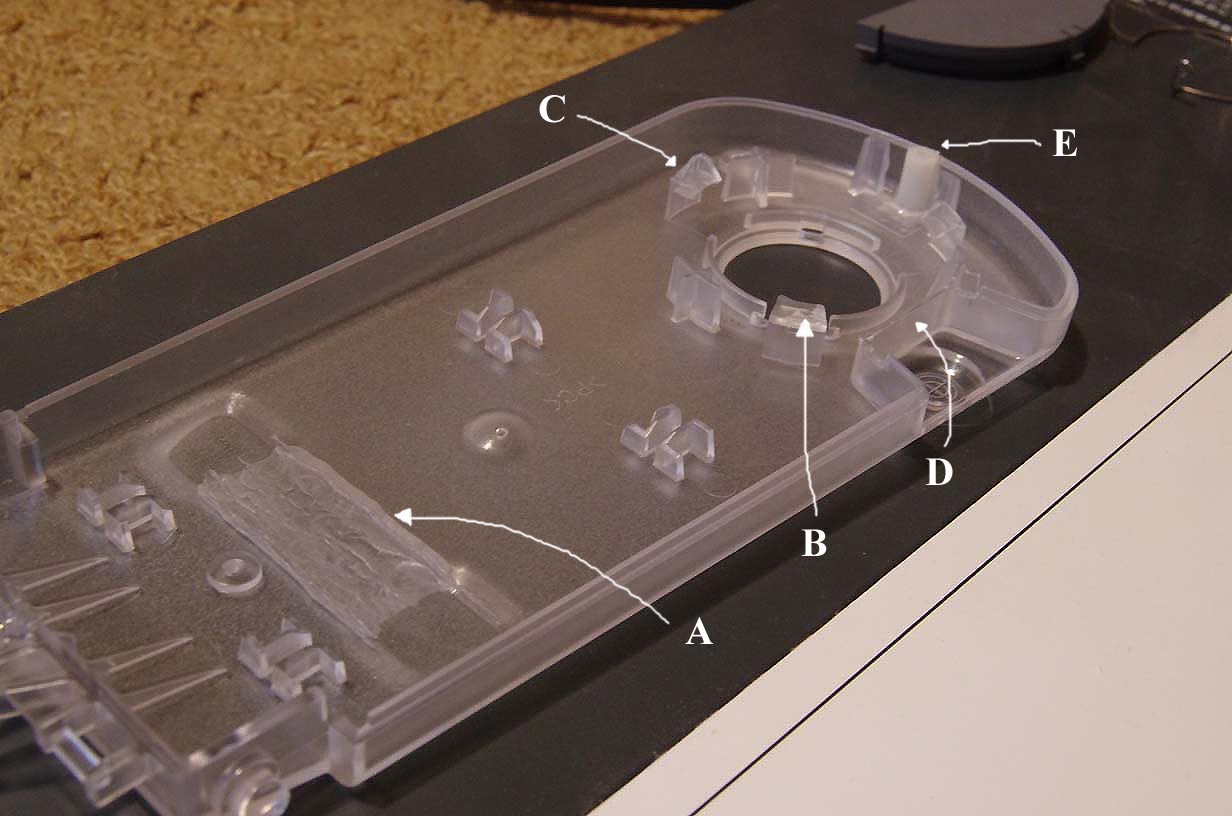

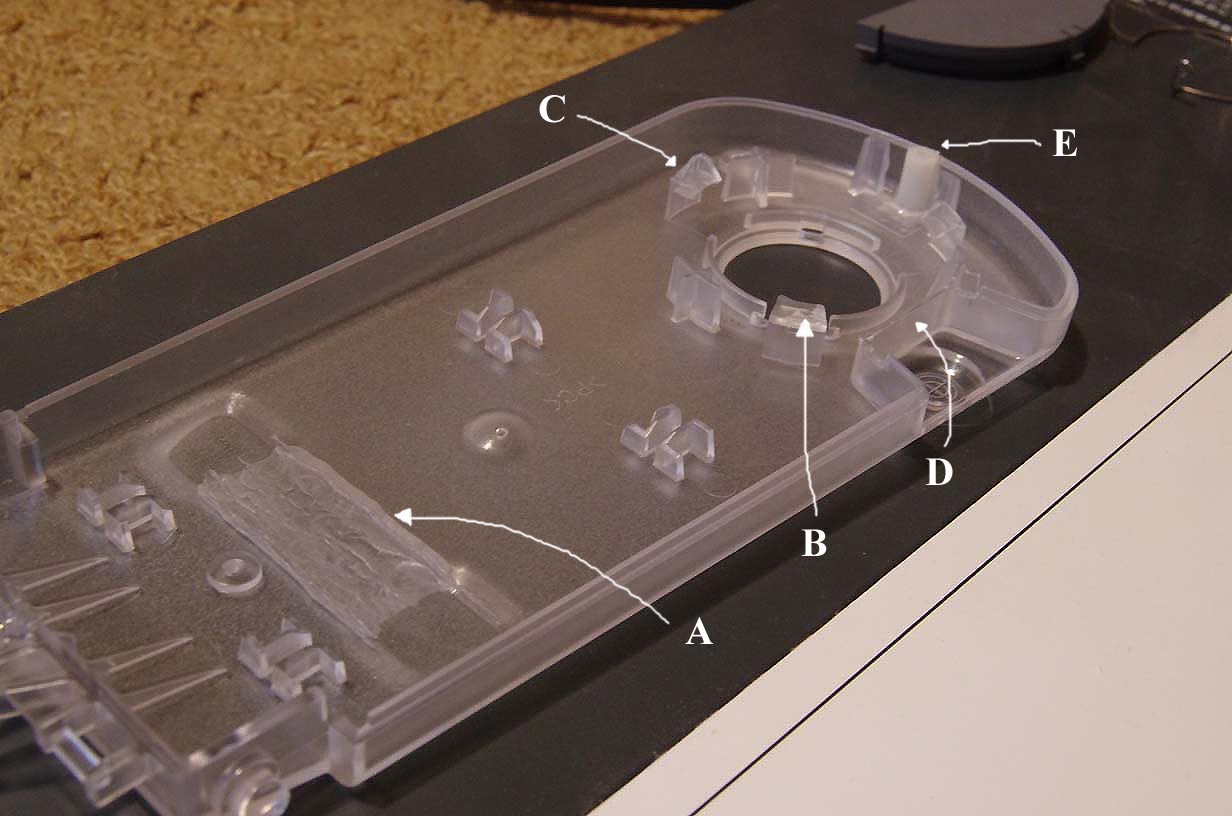

The bottom plate needs some subtle but careful modifications. One is

to extend the two depressions at the

heel of the instrument so that they join. (see "A") It doesn't have

to be exactly the same level, but within

a 0.1 mm or so of it. One approach would be to use a drill stand

that can be locked off in combination with

a small milling or cutting tool. The tool can be held at a fixed

spacing while the plate is slid one way and the other.

You want to avoid touching the existing depression surfaces, as they

establish the instrument level.

I used a high speed hand held rotary tool, and a variety of

attachments (such as a small

cutter, larger cutter, cutting wheel etc.) to perform the

modifications to the foot.

There are thee clips on the bottom plate that hold the aperture ring

in position, and two of them

need a slight modification. (The official X-Rite i1pro2 foot seems

to have a more sophisticated

locking arrangement than this.) The one at the 5 O'clock position

needs the sloping guide on the top of

it removing completely (see "B"), while the one at the 9 O'clock

position needs it half

removing (see "C"). This is to allow for the body of the instrument

having less clearance

in these areas. The cut-out for the visual location guide also needs

shaving slightly, to accommodate the

lower body of the instrument (see "D"), and laying the instrument

into position will act as a guide as

to how much to remove, and making sure that the instrument now clips

properly into position.

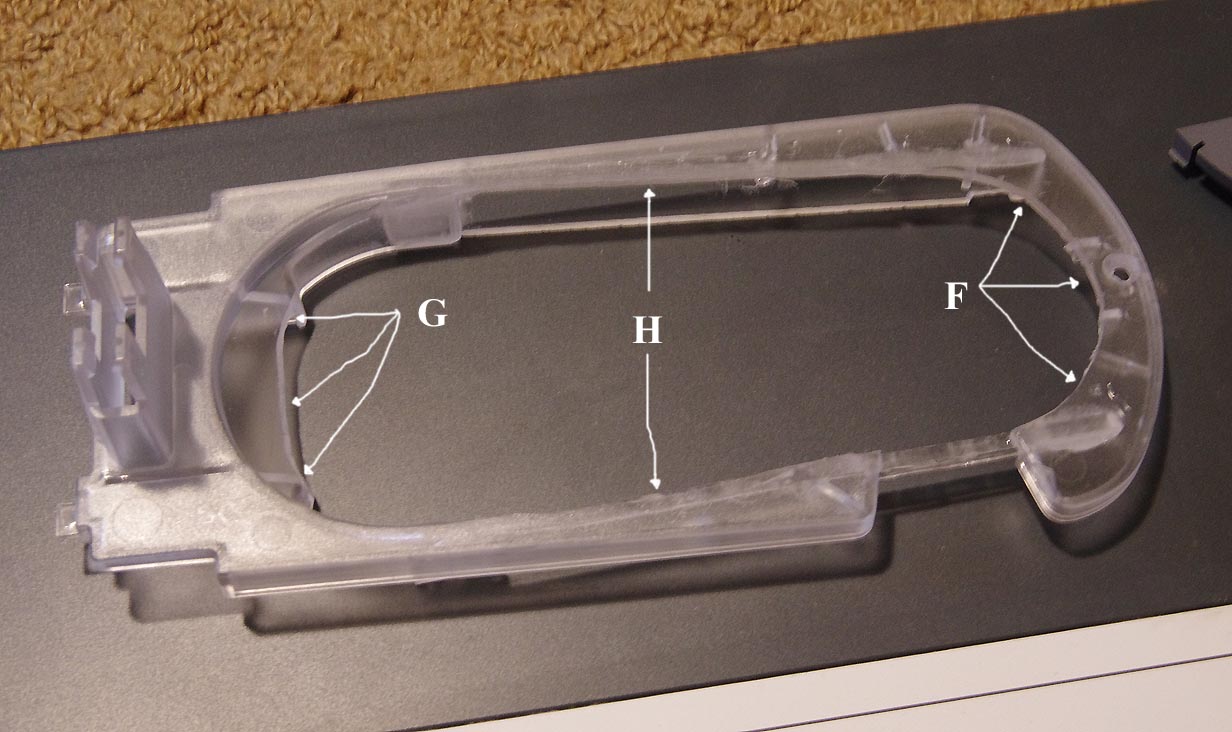

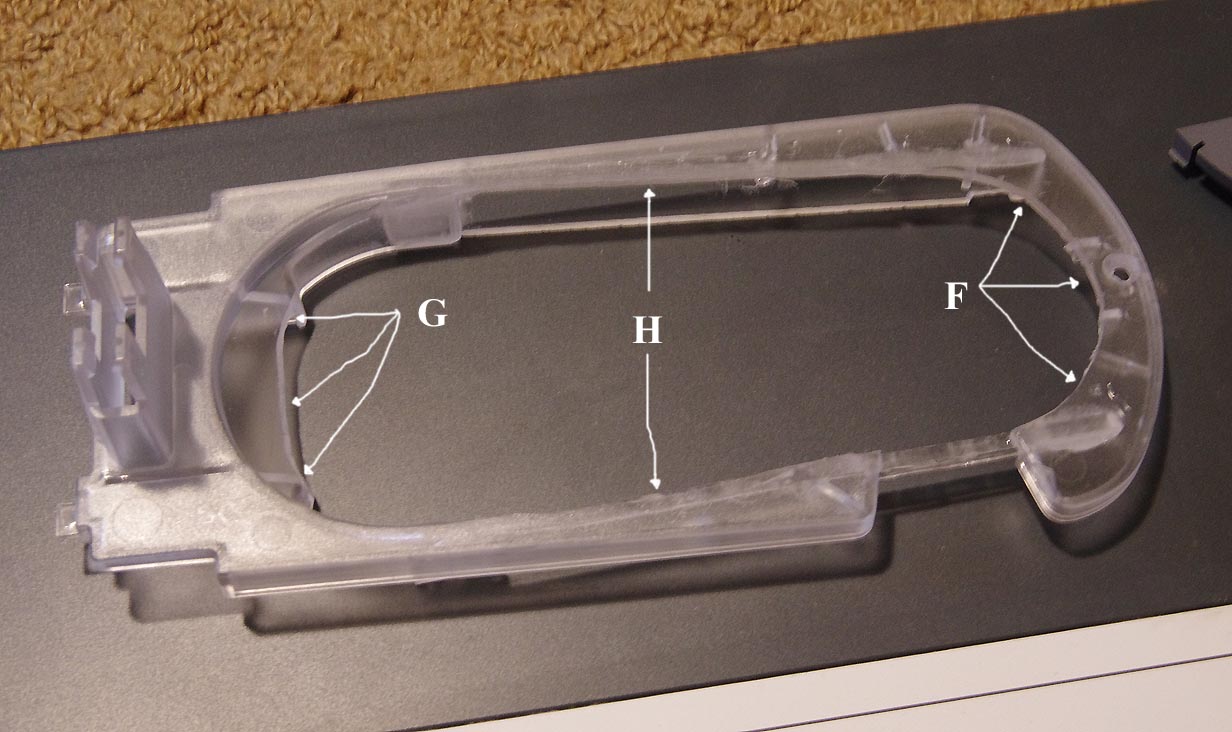

The upper plate needs much more extensive modifications.The half

circle at the head end needs

expanding in radius by 2-3mm (see "F"), while the heel needs carving

away to join the two wells

allowed for the i1pro foot. (see "G") Two straight cuts are needed

from the heel half circle to the

head half circle (see H). A great deal of ribbing will be cut away,

and the cut-out for the location

guide will become completely detached (the connection remaining in

the above photo is a new

bridging rib - see below). Once again, the instrument can be used as

a guide

as to how much to carve away. You're done when you can clip the

instrument into

the combined upper and lower plates, with a minimal amount of extra

clearance or slop around it.

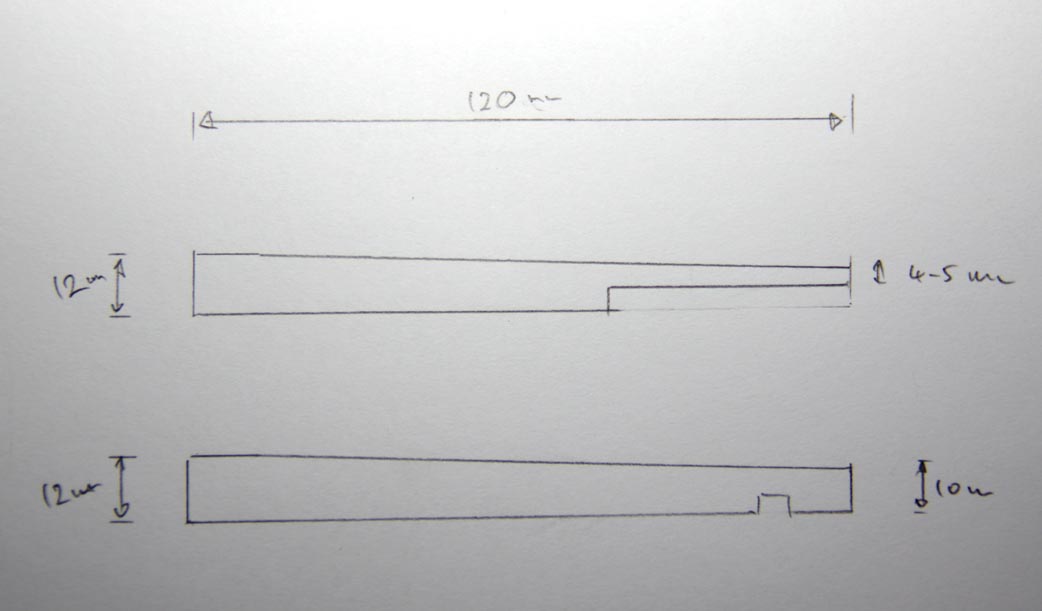

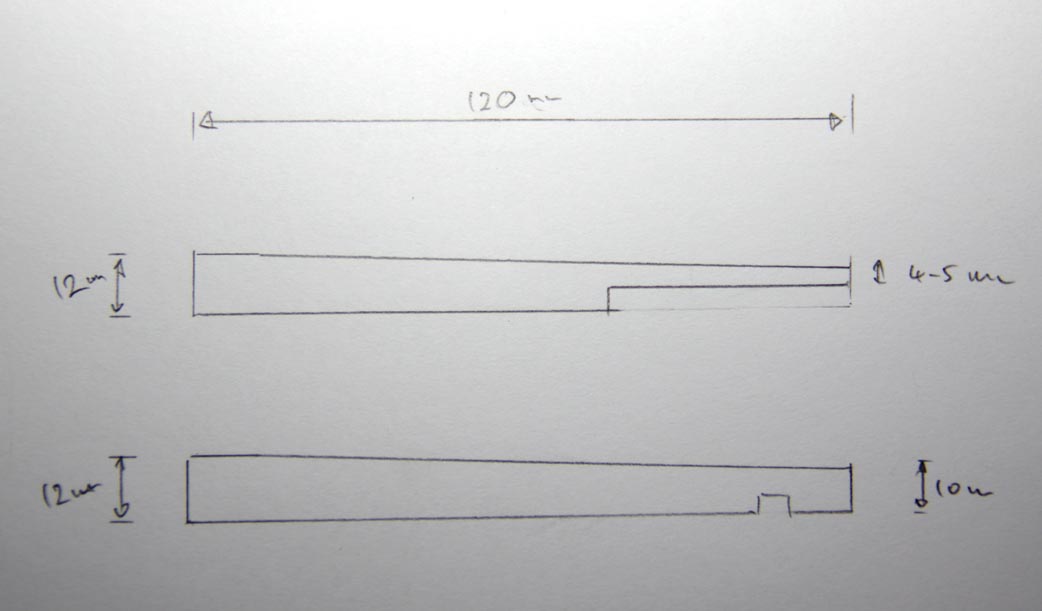

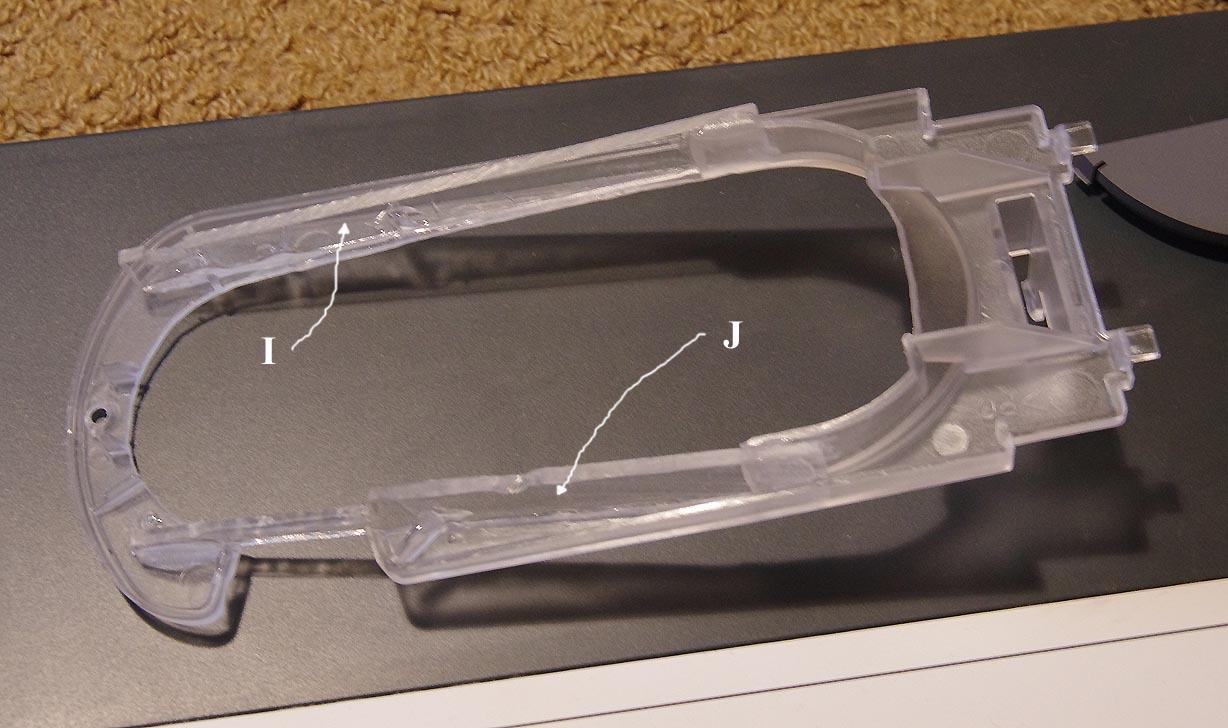

Reconstruction

The upper plate will have been severely weakened in this whole

process, and now needs

strengthening. I cut two new ribs out of a piece of 2.5mm thick

clear acrylic, both

120 mm long and 12mm wide tapering to 10mm. One needs a cut-out to

allow

for a molding bump (see "I" below), and the other needs thinning to

5mm where it crosses

the location guide cut-out (see "J"). Some finessing is also needed

where they sit beside

the remaining main ribs at the foot. There is about a 10mm overlap

that will be glued and

used to project the foot support out to the top plate. Room needs to

be cleared

for these new ribs along their length, and the plastic prepared for

gluing by

roughening the surfaces where they will be making contact.

I cut down and shaped a 2.5mm threaded plastic spacer for the bottom

plate (see "E"

in the first photo), to use with a matching countersunk screw in the

top plate to take the place

of the original molded internal clip that fastens the two plates

together.

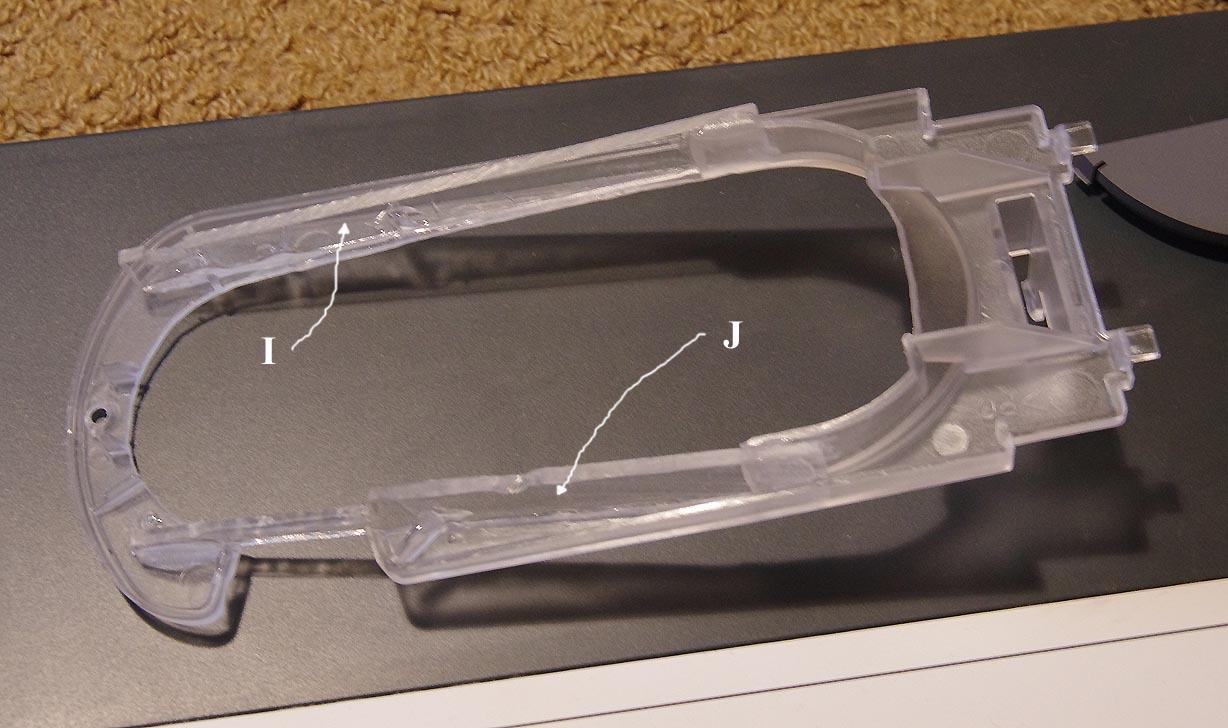

It's important to make sure that everything fits together again,

before moving to the next step

of gluing the new pieces into the top plate.

The new ribs are glued into place using a two part clear epoxy glue,

laying it upside-down to do this,

so that the bottom plate can be used to align the separated pieces

around the location guide. The 10mm

glued overlap at the heel is important in returning strength to the

top plate.

Re-assembly is the reverse of the disassemble.

You can then double check that the i1pro2 clips into the modified

i1i0.

The completed

modifications, ready for testing.

Hopefully you've found this article informative and/or entertaining.

Graeme Gill.